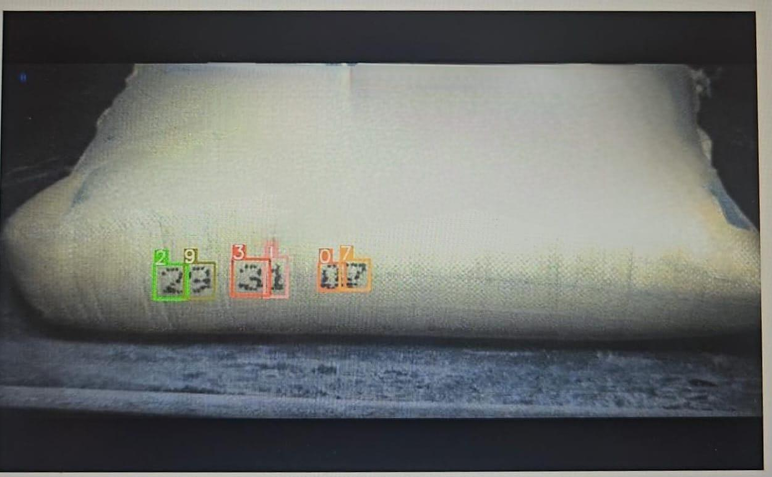

Detection, Recognition, and Verification of printed Batch Code on the side of the sack. Verification with Date, Month, or any standard metrics.

Application Area: Cement Industry, Rice and Feed Industry, Food Industry.

How It Works:

- Detection: The system identifies the location of printed text on irregular sack surfaces, which may include folds, wrinkles, or uneven textures.

- Recognition: Advanced AI-based OCR models read the batch code, manufacturing date, expiry, or MRP details.

- Verification: Each printed code is checked for correct date/month format, completeness, and alignment with expected values or reference data.

Features & Benefits:

- Custom AI Trained for Sack Surfaces - Capable of reading print on woven PP, cloth, or kraft paper bags, even in dusty or rough factory environments.

- Supports Non-Standard Fonts & Layouts - Can be trained for different printing styles, fonts, and ink spreads used in industrial sack printing.

- Standardized Format Checking - Validates codes against predefined date formats, month values, or product-specific identifiers to avoid misprints.

- Real-Time Rejection System - Connects with automated reject arms to remove misprinted sacks instantly from the production conveyor.

- High-Speed Inline Performance - Supports high-throughput inspection on fast sack-filling and stitching lines without slowing production.

- Data Logging for Audits - Captures every inspected image and result for traceability, reporting, and compliance purposes.

- Adaptable to Multiple Applications - Suitable for cement bags, grain sacks, chemical fertilizers, animal feed, and flour mills.

Application Areas:

- Cement Manufacturing Plants

- Rice Mills & Grain Exporters

- Cattle & Poultry Feed Production

- Bulk Food Packaging Units

- Chemical and Fertilizer Industries

If you’re looking for accurate, automated batch code inspection for large-format sack packaging, the BT Print Sack OCR System provides a rugged, scalable, and industry-ready solution.