In industries like pharmaceutical manufacturing and metal component production, the quality and precision of needles is non-negotiable. Whether for syringes, cannulas, or industrial nozzles, even minor defects can compromise safety, performance, and compliance. BT Print’s AI-powered Needle Inspection System ensures that every needle meets stringent quality standards for geometry, alignment, and sharpness.

What Does the Needle Inspection System Do?

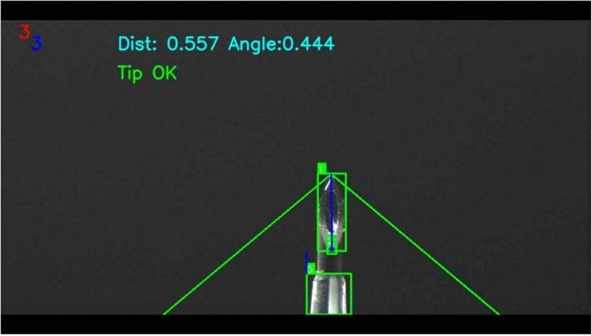

Using advanced AI-based vision technology, this system performs high-accuracy inspection of:

- Needle Tip Sharpness – Ensures the point is correctly formed and suitable for piercing or application.

- Height Measurement – Verifies the vertical distance from the needle tip to the plastic hub or base, ensuring correct length.

- Angular Alignment – Measures the angle between the needle tip and its seating point at the bottom hole to detect any bending or misalignment.

Features & Benefits:

- High-Precision Tip Detection - Identifies whether the needle tip is sharp, blunted, or malformed.

- Dimensional Accuracy - Confirms the exact height of the needle for each batch, matching design specifications and medical compliance.

- Angular Inspection with AI - Checks for bend or tilt using angle detection algorithms to ensure proper alignment from tip to base.

- Real-Time Rejection Mechanism - Automatically removes defective units without halting production flow.

- Multi-Camera Setup (Optional) - Covers different views (top, side, angle) to detect complex defects in high-speed environments.

- Adaptable AI Models - Trained on a wide range of needle types, this system can handle variations in material, finish, and reflection.

- Data Logging & Quality Reporting - Includes cloud-ready inspection logs, inspection reports, and trend analysis for process improvement and audit compliance.

Application Areas:

- Pharmaceutical Industry: Syringe and cannula inspection

- Surgical Equipment Manufacturing

- Veterinary Medicine

- Metal and Alloy Needle Fabrication

- Nozzle Production for Industrial Use

Ensure every needle you produce is sharp, safe, and standard-compliant with BT Print’s advanced Needle Inspection System. Powered by AI and machine vision, this solution delivers unmatched reliability in critical component inspection.