Precision in cap placement is vital for ensuring product quality, leakage prevention, and consumer trust—especially in high-speed juice and beverage production lines. BT Print’s AI-based Cap Positioning Inspection System is engineered to verify not only the presence of the cap but also its exact position and angle in real-time.

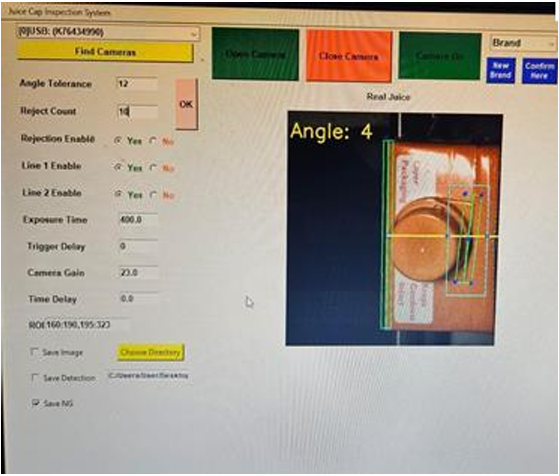

Using advanced object detection algorithms, this system detects the edge of the juice box or bottle and calculates a reference detection window. It then evaluates whether the cap falls within the correct boundary and identifies misaligned or improperly sealed caps with high accuracy.

How It Works:

- The AI camera first identifies the edge of the container using object detection models trained on juice boxes and bottles of various shapes.

- It then defines a cap positioning window based on the ideal alignment and spacing.

- Once the cap is detected, the system analyzes its position and angular orientation.

- Any deviation from the defined limits triggers a rejection signal, removing faulty products from the line before they reach secondary packaging.

Key Features & Benefits:

- Cap presence, alignment, and angular orientation check in one unified system

- Works with Tetra Pak, PET, HDPE, and glass bottles

- Edge-detection based localization ensures accurate calculation of the cap window

- Supports varying cap types: screw caps, flip-tops, and snap-ons

- Detects missing caps, off-center caps, and tilted caps

- Adapts to high-speed production with minimal latency

- Reduces manual visual checks and increases consistency

- Ensures product safety and brand credibility in the competitive beverage market

- Integrates seamlessly with PLCs, conveyors, and rejection units

- Provides production analytics and fault logs to optimize line performance

This solution is ideal for juice manufacturers, dairy product packagers, soft drink brands, and edible oil lines where precise cap positioning is essential for leakage prevention, consumer safety, and regulatory compliance.

As part of BT Print’s AI Inspection Suite, the Cap Positioning System helps you automate quality control while reducing manual labor, increasing efficiency, and minimizing customer complaints.